It is strange how the word ‘myth’ is used negatively in the risk and safety world as if to declare something as a myth, is an in-truth. How we determine what is true, real and effective is not that easy. All myth is anchored to faith, not evidence. Most often we develop myths according to our … [Read more...] about When Myths Collide in Risk

SAFETY MYTHS

Myth as a Helpful Way of Understanding Risk

Myth is a very useful genre when one tries to understand a wicked problem like risk and safety, fallibility and culture. When one understands what myth is (https://safetyrisk.net/understanding-the-myths-and-metaphors-of-safety/) then Risk Makes Sense … [Read more...] about Myth as a Helpful Way of Understanding Risk

Understanding The Myths and Metaphors of Safety

In risk and safety, we cannot separate the language we use and its bias, from the way we participate subjectively in our thinking and speaking in risk. The metaphors we use come from our unconscious use of language and condition the way communication is received. See further Metaphors We Live By … [Read more...] about Understanding The Myths and Metaphors of Safety

Sacred Objects to Remember Un-Safety

To study Mythology is to Study the way humans construct meaning and purpose in living. We see this in how people make things sacred and profane (https://safetyrisk.net/the-sacred-and-profane-rituals-and-semiotics-a-lesson-for-safety/). We will see much of this in Australia on 25 April, ANZAC Day. … [Read more...] about Sacred Objects to Remember Un-Safety

Understanding Mythology, Myth, Mythosphere and Science – A Podcast.

For those who want to understand the nature of myth and mythology perhaps this podcast may help: When we use the word ‘myth’ in SPoR we don’t mean fantasy or fairy tale because, myth is unique and is semiotically and poetically verified. Similarly, the myths of scientism that are popular in … [Read more...] about Understanding Mythology, Myth, Mythosphere and Science – A Podcast.

What is Safety? Video

By Nippin Anand Here's the second in a series of podcasts about safety with Greg Smith. Some you you may have seen the last video (https://safetyrisk.net/two-new-videos-from-novellus/ ) in this series where we discussed how far the industry has onboarded his wisdom about papersafety. The … [Read more...] about What is Safety? Video

The Meaning of Myth in Risk

Yesterday was our second day on exploring mythology, risk and safety. As we got to know what myth was more as a genre we were more sensitised to how myth works both in society but more importantly to be more sensitised to how myth is employed in safety. This was amplified by a semiotic … [Read more...] about The Meaning of Myth in Risk

Myth Making and Why it Matters to Safety

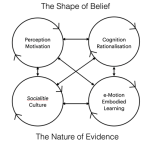

It was great to see some new and old faces as we commenced our workshops on Mythology and Embodiment in risk. Craig did some great groundwork on Concept Mapping myth and the Linguistics of myth as well as work on models and the myth of the Scientific Method. I started out by exploring … [Read more...] about Myth Making and Why it Matters to Safety

The Power of Safety Myths

This week we are running two workshops in Canberra on Mythology and Embodiment. These are two critical issues that people in safety ought to know about. Why? Because so many activities of safety are attributed as effective when they are not and so many beliefs that are held are simply myth. You can … [Read more...] about The Power of Safety Myths

Tackling the Challenge of Heuristics in Safety

The recognition of heuristics as the foundation for all human decision making is critical to skill development and implementation of SPoR (https://safetyrisk.net/spor-and-disposing-of-bad-myths/) in the workplace. One of the silly myths of behaviourism in safety is the complete ignorance of … [Read more...] about Tackling the Challenge of Heuristics in Safety