Is There Safety In Numbers?

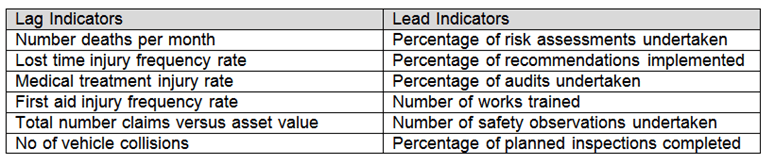

There seems obsession to measure health and safety at present and this often done through the use of so called lag or lead indicators. The majority of these include a number based system for monitoring ongoing performance. A few examples of these are included in the table below:

This particular site has 218 KPI safety downloads available and the majority are number based

www.intelex-exchange.com/product/downloads?t=scorecard

It is also quite common for companies to set targets for completing a numbers of lead indictors per week and this also becomes a key statistic. The problem with this, is it pushes people into compliance mode and often results in increased paperwork without really adding too much value. In doing so the company develops a “ have to” necessity, instead of a “want to” philosophy

The fact is, every time you devise indicator and turn it into a KPI it naturally becomes a lag indicator, it becomes a measure of the input rather than output

What is needed, is not an increase in inputs (numbers) but an improvement in the quality of the improvements ( outputs) if we are to stand a chance of significantly reducing death and serious injury rates globally

So instead of measuring the number of people trained in health and safety, why not evaluate the performance of the trainer and knowledge gained. Instead of recording the percentage of accidents closed out, why not evaluate the effectiveness of the new control measures introduced. And, instead of quantifying the number of contractors approved per month, evaluate the effectiveness of their new systems introduced as a result

If Indicators are to become beneficial, they must relate directly to the company’s core vision and goals and identify that the management of health and safety is not only effective but consistent (are we doing the right things regularly?)

If a core goal is to improve employee ownership of systems, Instead of counting the number of forms completed, ascertain if they have been completed correctly and ask questions to see if they have been comprehended by those people utilizing them. Instead of counting the number of near miss reports, evaluate what changes were made to reduce future repeats

For indicators to be effective in the face of competing demands, they need to be targeted towards the biggest risks and challenges that are occurring within the business and limited to a small number which focuses on quality not quantity that fosters a drive for continual improvement

With wisdom we can use indicators as a guide for action, but we need to understand the characteristics of the data that go into them. We may be obliged to report them, but we should not fool ourselves (or others) that a KPI conveys any meaning without further description of context and how the data varies by site, region and culture over time

For that reason, I don’t believe indicators should not be shared or benchmarked against other organizations and certainly not used as leverage for gaining work in competitive tenders. Instead I suggest you create indicators that are useful for the business, using its own data and outputs as our local guide for tracking improvement

No matter what indicator you decide to use, the most important question that should be asked is “can it be understood and utilized effectively by the workforce?” Will the desired outcome be a true reflection of what is happening within the business; or will the result be manipulated just to make the business/person look good?

Mark Taylor – Director

Safety Matters (NZ) Ltd – www.safetymatters.co.nz

Do you have any thoughts? Please share them below