Thermographic Scanning or IR Thermography

Thermographic scanning (also known as Infra Red scanning) is used as a predictive maintenance tool for plant and machinery. This technology has particular application for electrical systems and has the ability to identify electrical connections that could possibility fail in the future.

Thermographic surveys use an Infra Red camera to view electrical systems and identify connections that are operating at a higher than normal temperature. If a connection is not electrically sound due to looseness or corrosion then the connection has a higher resistance resulting in a higher operating temperature. The advantage of the Thermographic scanning is that it is carried out with the equipment operating under normal operating conditions.

Benefits of Thermographic Scanning

- Reduced electrical fire potential by identifying faulty connections

- Minimising breakdown potential in production processes

- Able to identify preventative maintenance needs which can then be planned

- Reduced risk of fire, mechanical breakdowns and business interruption

Scanning Process

The Thermographic scanning process is carried out with machinery and equipment operating under normal load conditions. It is preferable to be able to scan equipment when operating at its maximum operating capacity if possible. If electrical systems are not live or are not carrying current then there is no point of scanning this equipment.

Thermographic scanning relies on a direct line of sight to the equipment or surfaces being scanned for temperature variations. For this reason the main task with carrying out Thermographic scanning is the opening or removing of covers over switchboards or connections. An electrician is required to remove covers and open switchboards and this should be arranged prior to the commencement of the survey.

Report

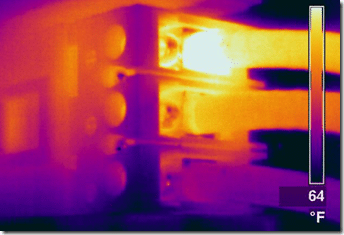

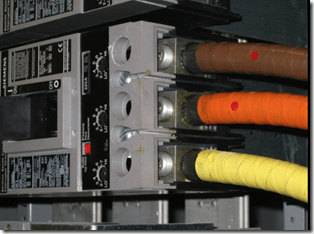

After the scanning is completed and any potential faults have been identified a report is produced. This uses images of connections saved electronically to the camera. A digital photo is also taken and used as a reference to identify the location of the connection and equipment.

The report will show a color image of the potential faults and make comments as to problem and possible solutions or rectification required. The problem is also prioritized as to the level of attention required.

Do you have any thoughts? Please share them below