“The Right thing” ( Scream or Strangle)

In the process of training up to become a Safety Professional, I was also training for my Surface Shotfirers tickets and licensure. In other words I was getting the training and permits to blow stuff up – I am talking 90,000 tonne of the earths surface at a time. A few open cut mining terms for clarity of what follows.

Bench – surface on which drilling of blast holes occurs (Patterns being used this day, 360 blast holes).

Free Face – near vertical ‘Drop Off’ from one working ‘Bench ‘ to another (on this occasion 18 mtrs)

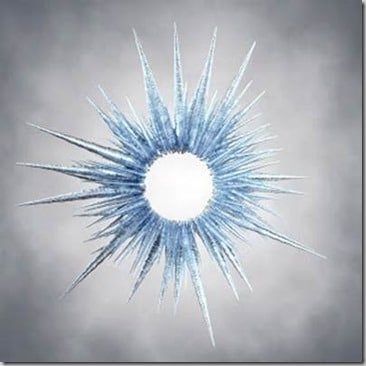

For those of you that have never even seen a Open cut Mine, imagine if you will, a pane of glass which a cricket ball has gone through.

“image courtesy of RickThompsonDesign.com”

Lay it horizontally and magnify it several thousand times. The hole is now about the length of a aircraft landing strip in diameter. The distance from the bottom to the top of the hole is 18 meters. You now have effectively, much of the structure of an open cut mine. Notice the fracture lines running from the hole to the outside. Same thing happens on a open cut mine site, only the fracture lines can be 150 to 200mm wide and the closer to the ‘Free Face’ one gets, the more of these fracture lines occur and the less stable the ‘Bench’ surface you are working on becomes. Now imagine you covered this sheet of glass with a layer of paper with the hole cut out. You can’t see the fractures, this is what happens on a open cut mine bench, the fracture lines get covered by material from the drilling rigs, steaming for the blast holes, movement of machinery and work crews.

As a result of this inherent ground instability (for reasons given above), Safety management systems for the open cut mine site I was on, required no machinery to be within 5 meters and no human to be within 1 meter of top edge of the ‘Free Face’ (other distances required for bottom edge). To assist in compliance and as a visual reminder, Safety Barrier tape was strung on star pickets 1 meter back from the ‘Free Face’. Effectively creating a ‘Fence’.

The blast crew of ten comprised one senior Shotfirer (35 years’ experience), two Shotfirer assistants (1-3 years’ experience), myself as Shotfirer Trainee (6 months experience) and labourers, had laid out the required number of down hole delays and 400gm boosters and were about to start loading the blast holes with progressively assembled primers (Booster + Det = Primer). It was at this point I noticed, to my horror, that the Senior Shotfirer was:

· on the wrong side of the safety barrier tap, with

· his back to the ‘Free Face’ (18 mtr drop)

· his back heel aprox 20 cm from the edge and

· checking messages on his mobile phone.

Now there is a part of me that wants to instantly SCREAM at him, for blatant disregard for:

1. his Personal Safety

2. Company Safety Policy and Standard Operating Procedures

3. The Example set for others to follow

Another part of me wants to STRANGLE him (from 10 meters away) for all of the above, plus the Stress:

1. he is causing me (I can feel the adrenaline and blood pressure climbing) and

2. would cause to the Rescue Team sent in to retrieve him

3. would cause to his family and friends

4. would cause to all work crew that knew him and Management regardless of knowing him or not.

It is amazing how fast these thoughts along with calculations of the ‘Speed of Gravity’ tore through my mind. Option so far – Scream or Strangle. I refrained from Screaming – I calculated that sudden movement or action could startle him, causing him to step back and then I would be a direct contribution to his injuries or worse. I did a quick mental check of my Verified Operationally Competent abilities – Strangulation from 10 meter was not on the list.

The next best thing, I signalled him (arms waving madly in the air) to come to me. Once he was on the ‘Correct’ side of the Safety Barrier Tape, I then walked to him and expressed my concerns. Candidly pointing out that had anyone else engaged in the conduct he had just displayed, he would have ‘Terminated’ their employment and had them escorted off the site. He has never spoken to me since, but at least he can still play with his grand kids.

From my perspective, I find two major groups sustain permanent life changing events (we try not to call them ‘Accidents’ anymore, as there is the mentality that accidents are ‘unavoidable’) . Those with little or no experience – the Green Skins, Newbies including Apprentices and the second group being the long tooth, grey hair/no hair ‘Experienced’.

The Green Skins, are still learning. They frequently run with the mentality that ‘If it does not kill you, it makes you stronger’. They require significantly more supervision, monitoring and event challenges.

The Experienced – by human nature, attempt to make life easier, eventually take short cuts and find ways to do ‘What they can get away with’. In short they become complacent. This group needs ‘Reminding’ that they are not Superman – not bullet proof and they are the ones that set the example others will copy or blame if the example is poor.

You work in a world where everything around you, is Corrosive, Explosive, Toxic or Carcinogenic and with plant and equipment that can instantly Crush, Cripple you for life or Kill you. Continual Respect for your environment – that is everything around you, that is essential to your survival.

Knowing the “Right Thing To Do” is not difficult. Training others in the “Right Thing” is not difficult.

Doing the “Right Thing” takes effort, continual effort – Is your life, the life of a workmate – are they worth it. The answer is Yes. Put the effort in. Keep putting the effort in. Make a difference.

Karl Cameron

Do you have any thoughts? Please share them below