Robots eliminate injuries for small business too.

Guest Post

When the topic of robotics comes up, many immediately start thinking about expensive, complicated technology which is out of reach for small manufacturers.

When the topic of robotics comes up, many immediately start thinking about expensive, complicated technology which is out of reach for small manufacturers.

It wasn’t that long ago that might have been the case; however that is all changing thanks to a new generation of easy to use, low cost robotic solutions. Also fuelling this change is the ever rising cost of labour and an increasing awareness of manual handling injuries.

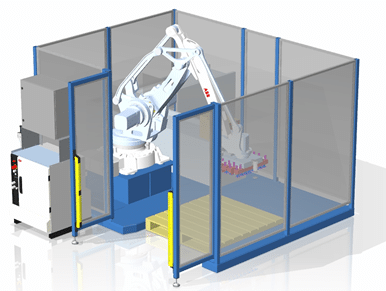

Consider automatic palletizing; within the hierarchy of controls it’s the best way to eliminate manual handling injuries but it has often been hastily dismissed as not practicably possible in the past.

Instead companies have opted to retain the manual process and implemented engineering aids such as lifting hoists, pallet lifters and rotators, only reducing the risk of injury, and increasing operation costs. But there is a better way…

An efficient, easy to use robotic palletizing system such as that offered by Robotize, can cost as little as $38,000 pa, can do the work of 2 people, and will work multiple shifts at no extra cost.

Even a small manufacturer operating just a single production line 40 hrs per week would not only eliminate the risk of injury as required by the OHS Regulations, but would also improve cash flow and reduce annual operating costs. Not only reasonably practicable, but it also good business sense.

To learn more about robotic solutions, talk to a Robotize representative today.

Ph. 1300 916 431

By Wade Leslie, Director, Robotize Pty Ltd

Do you have any thoughts? Please share them below